Connections

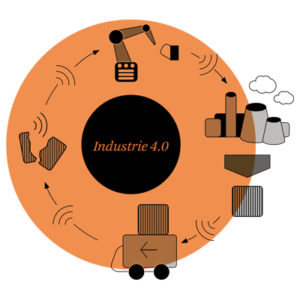

The fourth industrial revolution has begun.

Industry 4.0 is the current catchword for automation technology.

After the steam engine, mass manufacturing and digitisation, we now appear to be on the threshold of the fourth industrial revolution. This affects us all, as it comes not only with introduction of new technology, but also a permanent restructuring of economic, employment and social frameworks.

Opportunities for Germany.

Even the strong German economy is feeling the impact of globalisation, as it is now faces competition from low wage countries. Demographic change brought about by an ageing society has also resulted in a shortage of qualified

labour. Industry 4.0 could be the answer to these challenges. The integrative, highly efficient manufacturing concept is a solution for more flexible and less expensive production that is sustainable and satisfies global requirements. The high level of automation will therefore master both economic and social challenges.

Perfect interaction.

Industry 4.0 is based on information exchange. All components communicate with each other and share data. This means, for example, that a chipped vehicle component can report its impending breakdown and initiate the production and installation of a replacement.

Man kann nicht nicht kommunizieren.

The idea behind Industry 4.0 is the all-encompassing networking and integration of production equipment, data bases and products. Networking is possible as a result of the progressive miniaturisation and optimisation of computer chips. Today, even the smallest computers can share information via the Internet or Cloud.

Intermediate products provide machines with instructions via barcode or RFID chip. They are adaptive and ensure that machines operate correctly. The communication of all objects with each other as well as autonomous decision-making processes create an Internet of Things where the real and virtual worlds merge into cyber-physical systems.

Intelligent networking is altering the entire production logic – not only in relation to machines, products and warehousing, but also logistics, after-sales service and marketing, as illustrated in the following example: a chipped vehicle part has built-in sensors that continuously monitor its condition. It automatically reports an impending defect, or wear and tear, to the operator and manufacturer. At the manufacturer’s, a machine autonomously processes the data received from the vehicle part and promptly produces the replacement part. As the worn part has also communicated its location, delivery and on-site installation of the replacement part can be scheduled automatically.

One concept, many advantages.

The high level of adaptability and quick change of product will make it possible to achieve an extremely high individualisation of production. These factors will enable highly flexible mass production in which even custom-built individual products are possible without significant effort. This mass customisation production concept is one of the key features of Industry 4.0. It offers the benefits of mass production (such as economies of scale, learning curve effects or simply automation), but can still cater to the growing trend of customised products.

Mitsubishi Electric is actively promoting 4.0.

The significance of Industry 4.0 for the German economy and Germany as a business location is evident in the fact that three sector associations – BITKOM (the German Association for Information Technology, Telecommunications and New Media), VDMA (the German Mechanical and Plant Engineering Association) and ZVEI (the German Electrical and Electronic Manufacturers’ Association) – have joined forces to define standards and take the project forward.

Mitsubishi Electric is also convinced by the idea and, as the largest automation supplier to the Asian market, has adopted the “German approach” to Industry 4.0 in Asia. Mitsubishi Electric is a long-serving member of the industrial associations VDMA and ZVEI and intends to play an even more active role in the definition of Industry 4.0 standards.

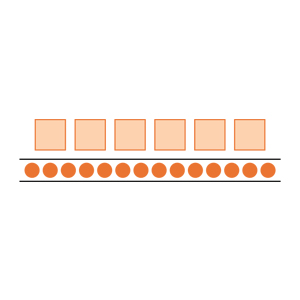

The industrial revolution

First industrial revolution:

Rapid mechanisation of factory operations after the invention of the steam engine.

Second industrial revolution:

Mass manufacturing is possible as a result of conveyor belts and electrical power.

Third industrial revolution:

The “digital revolution” resulted from digitisation and the widespread use of electronics and IT.

Fourth industrial revolution:

Industry 4.0 – networking the real and virtual worlds via cyber-physical sytems.

Changes No. 7

Please click on the picture to open the Changes No. 7.

Download

Download the latest Changes as PDF.

Subscribe

Subscribe for the print edition of our customer magazine “Changes”.